Hello everyone !!

Now Japan is in the celebration mood because of the birth of a giant

panda cub at Tokyo Ueno zoo and it has been five years since the last birth of a cub in 2012.

Its sex remains unknown, but both mother and cub are very well.

Everyone wish panda cub’s healthy growth and this kind of cheering news will continue.

So here goes the main part.

For today’s topic, we would like to introduce high heat dissipation PCB that can be utilized for high power module.

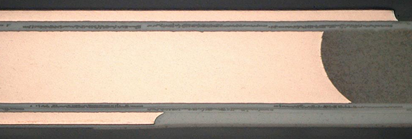

1. Embedded thick copper into organic PCB material(Already mass productio)

By adding copper filled via on top and bottom you can make

3layers PCB for high heat dissipation.

Cilinder volume of combination (Cu filled Via + Copper slug + Cu filled via)

is key for heat dissipation and thick copper is for thermal storage.

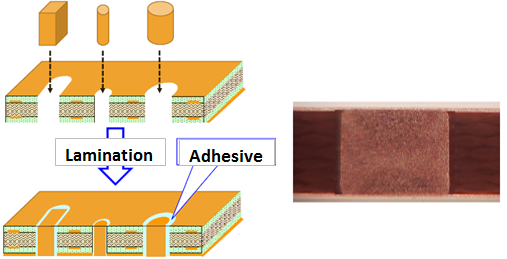

2. Structure with copper piller(Started mass production)

We can directly insert piller into holes.

Conventional one is done for pin insertion one by one(hole by hole)

It was pushed into holes by pressure and It often caused damage on plating wall in PTH.

We can make it all the pillers at one time by using particular tools.

Method to fix piller in holes are by using adhesive,

Therefore it never give damage to plating wall of PTH.

Cilnder volume of pin pillar is key for high heat dissipation.

Please feel free to ask us for any enquiries/RFQ about these solutions.

Thank you for reading!